Excel Arena – Smoke Extract Inverter Retrofit

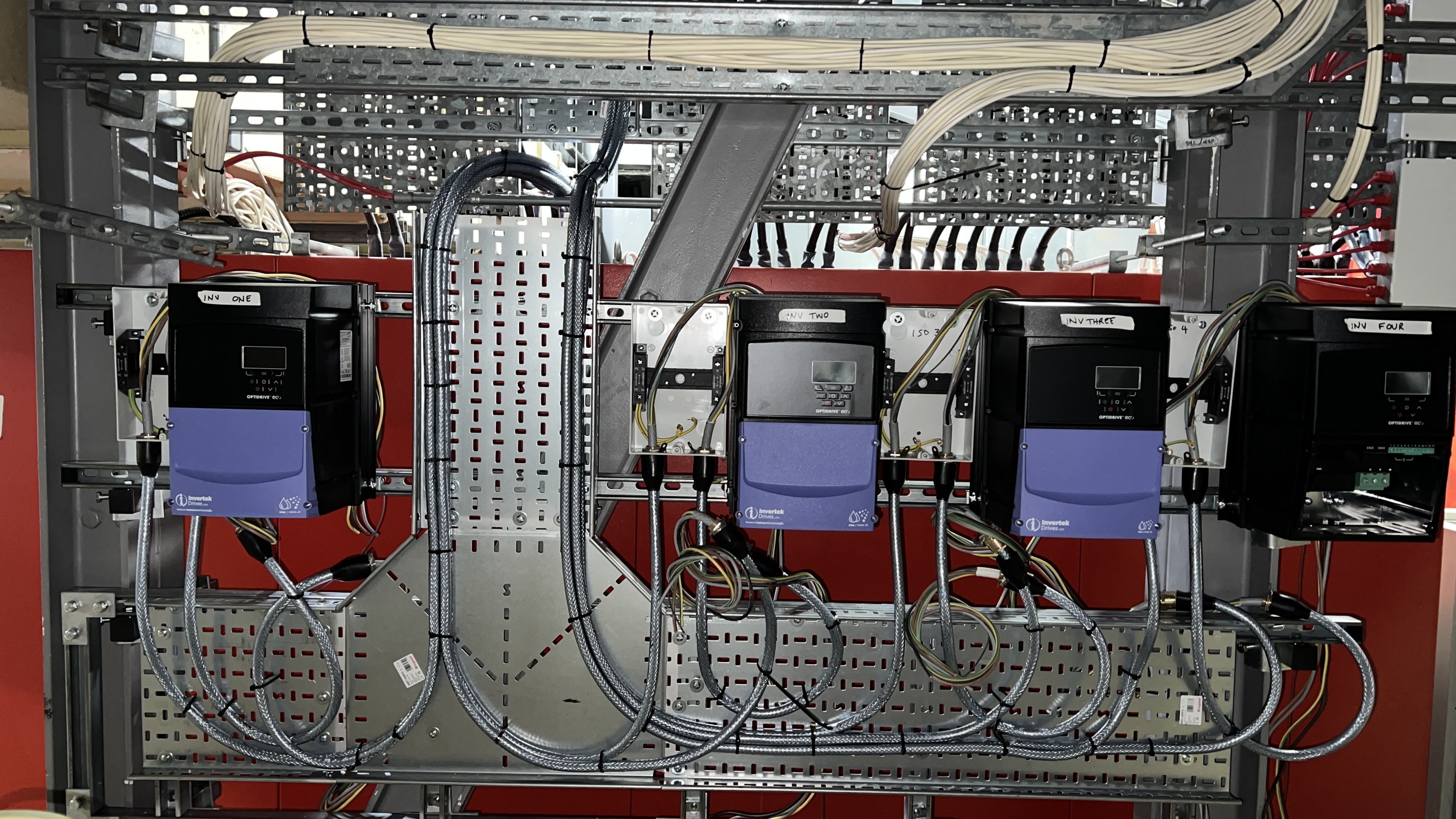

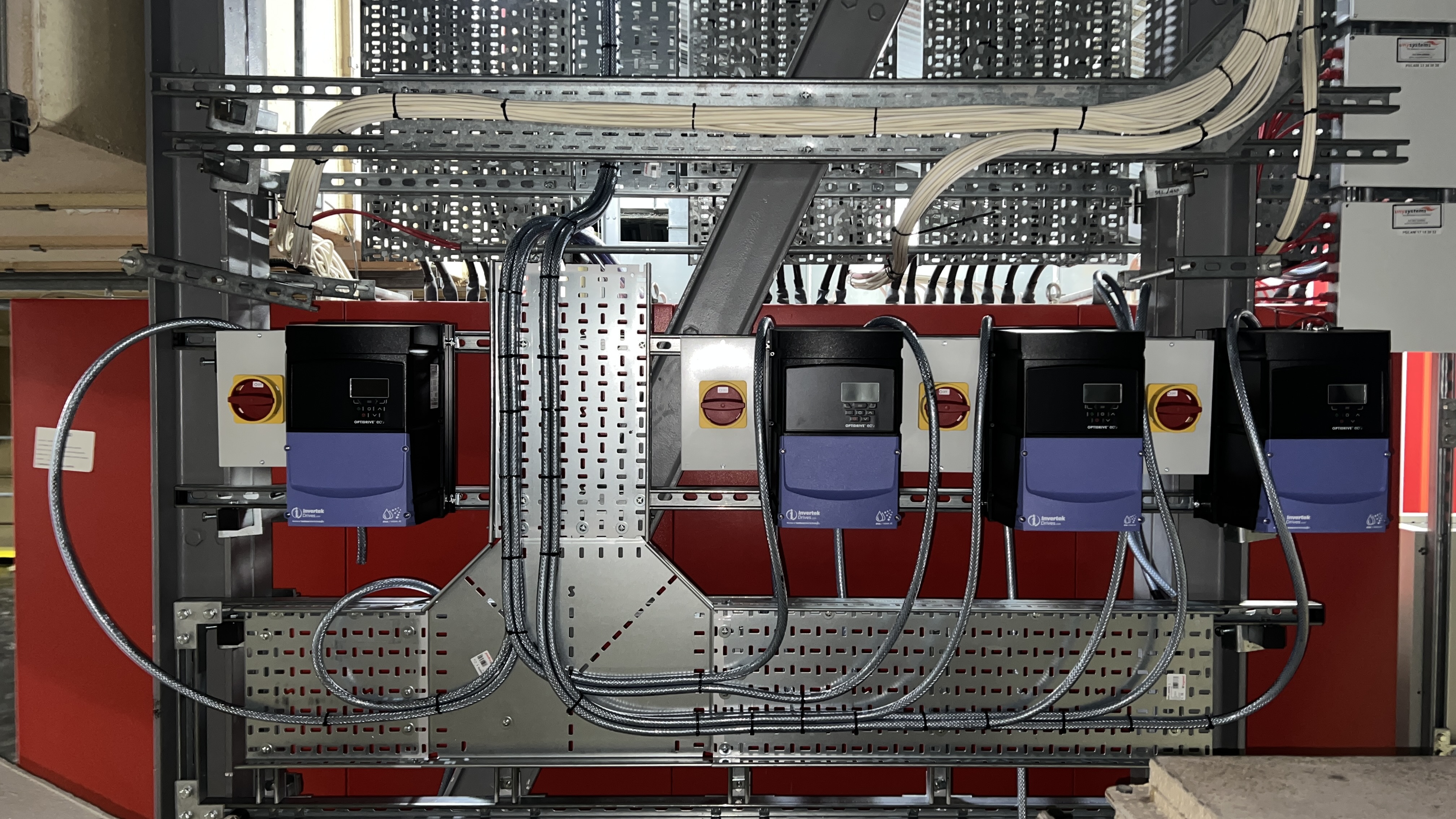

Alpha Controls retrofitted four new Invertek Optidrive Eco inverters at the Excel Arena to repurpose smoke extract fans into energy-efficient supply fans with full BMS integration.

Project Overview

Alpha Controls completed a specialist inverter retrofit installation at the Excel Arena in London Docklands, transforming four idle smoke extract fans into energy-efficient supply fans with full Building Management System integration. The project required precision engineering in a live plant environment, delivering a robust framework, high-quality cabling, and seamless BMS integration to enhance operational flexibility and energy performance.

The smoke extract fans, originally installed for emergency use only, remained inactive during normal building operations. By installing variable speed inverters, Alpha Controls enabled these fans to operate under controlled conditions, providing additional supply air capacity when required while maintaining full emergency smoke extract functionality.

Installation Framework & Containment

The installation began with the design and construction of a dedicated Unistrut support framework to mount the four Invertek Optidrive Eco inverters. The framework was engineered to support the weight and vibration loads of the inverters while allowing clear access for maintenance and future expansion.

Heavy-gauge galvanised cable tray and ladder rack were installed as the primary containment system, providing robust support for both power and control cabling. All tray sections were mechanically and electrically bonded, with bond straps installed at every joint.

Electrical & Control Wiring

All control and signal wiring used tri-rated cable and SY screened cable throughout to ensure electromagnetic compatibility (EMC) and long-term reliability. The cabling specification included:

- 4-core 1.5 mm² SY cable: For standard digital signals between BMS and inverter

- 6-core Type 1 SY cable: For multi-channel analog signals and control interfaces

- Special SY cable glands: To maintain screen integrity and provide EMC compliance

BMS Integration & Control Strategy

All control and signal wiring was integrated into the existing Building Management System to provide centralised monitoring and control:

- Run/Fault Status Feedback: Real-time confirmation of fan operation

- Speed Control: Analog outputs from BMS modulate fan speed via 0-10V or 4-20mA

- Energy Monitoring: Power consumption data transmitted to BMS for analysis

- Diagnostic Access: Remote interrogation of inverter parameters and fault logs

Energy Efficiency & Operational Benefits

By repurposing idle smoke extract fans for supply air duties, the retrofit delivers:

- Extended Plant Utilisation: Fans now contribute to building ventilation

- Variable Speed Operation: Up to 50% energy savings at partial load

- Improved Airflow Control: BMS modulates speed for optimal building pressure

- Reduced Mechanical Wear: Soft-start capability extends equipment lifespan

Outcome & Results

The Excel Arena inverter retrofit successfully transformed underutilised smoke extract fans into a flexible, energy-efficient supply air system with full BMS integration, soft-start operation, and professional installation quality ensuring long-term reliability.

Explore Our BMS ServicesTechnical Specifications

Equipment

- 4× Invertek Optidrive Eco Inverters

- Local Isolators (IP65)

- Unistrut Support Framework

- Galvanised Cable Tray System

Cabling

- SY Screened Control Cable

- Tri-rated Signal Wiring

- SWA Power Cables

- EMC-Compliant Glands

Integration

- Full BMS Integration

- Variable Speed Control

- Energy Monitoring

- Remote Diagnostics

Benefits

- 50% Energy Savings

- Dual Functionality

- Extended Equipment Life

- Improved Control

Need a Plant Room Retrofit or Inverter Installation?

Alpha Controls specialises in BMS retrofits, inverter installations, and plant room upgrades across London and the South East.