Watchmaker Court – MCC Panel Upgrade and Plant Room Control Retrofit

Complete MCC panel replacement and plant room control upgrade at Watchmaker Court in Clerkenwell, including full survey, bespoke panel design, installation, and integration with pumps, boilers, and BMS infrastructure.

Project Overview

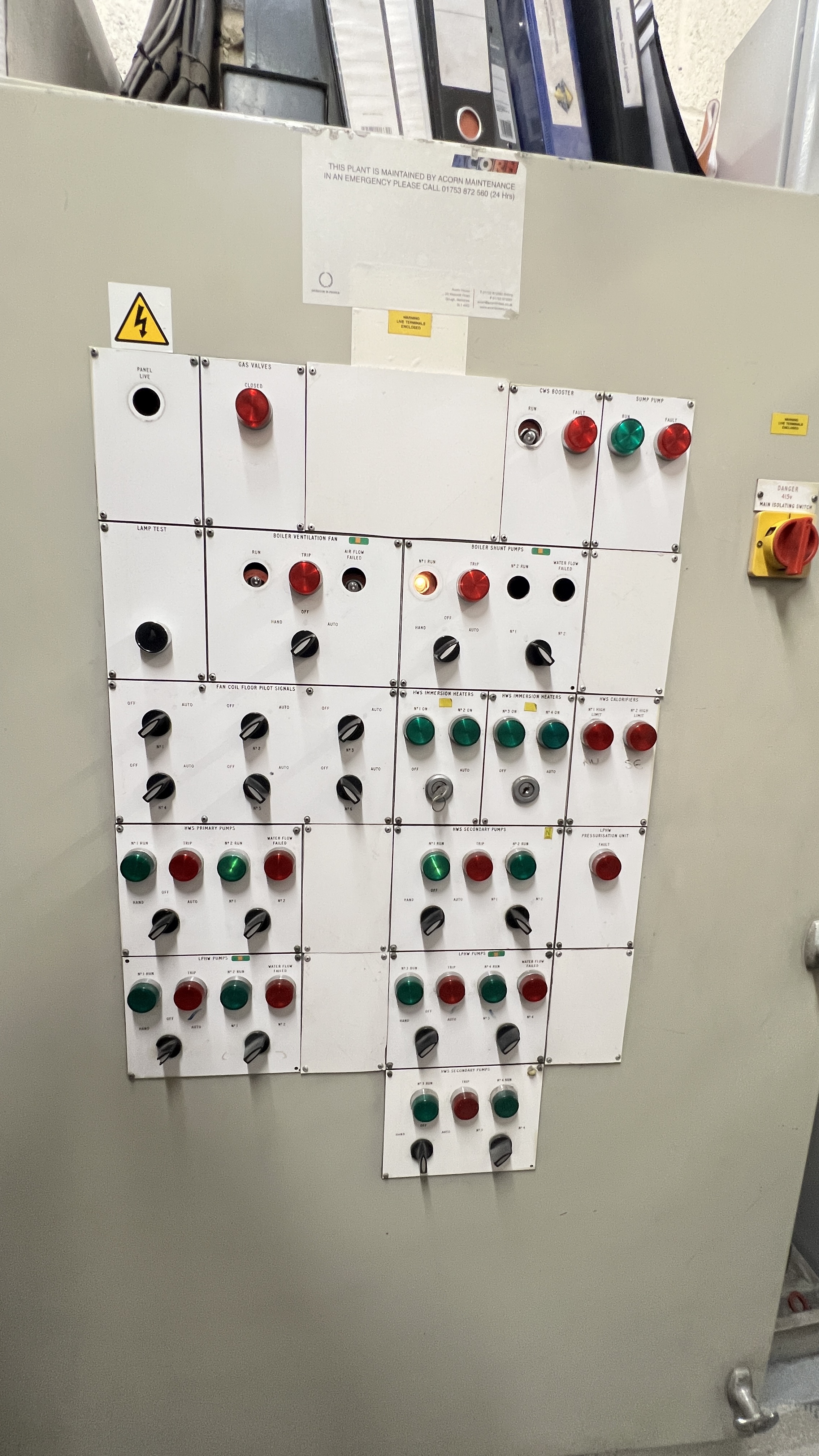

At Watchmaker Court in Clerkenwell, Alpha Controls delivered a comprehensive MCC (Motor Control Centre) panel replacement and plant room control upgrade. The project encompassed a full survey of existing mechanical plant, bespoke panel design and manufacturing, complete installation with new containment and wiring, and integration with the site's pumps, boilers, pressure systems, and Building Management System.

The existing MCC panel had reached the end of its serviceable life, with aging components, limited expansion capacity, and outdated control architecture. Alpha Controls conducted a detailed site survey to document every connected device, ensuring the new panel was built to exact specification with capacity for future expansion.

Site Survey & Design Phase

The project began with a complete plant room survey conducted during live operations to minimize disruption. Alpha Controls' engineering team documented:

- Heating Systems: Hamworthy FLEET F150 boilers with sequence controllers

- Pumping Systems: Primary and secondary circulation pumps with variable speed drives

- Pressurisation Units: Aquamaster pressurisation system with expansion vessels

- Inline Fans: Ventilation and extract systems requiring motor control

Panel Manufacturing & Installation

The new MCC panel was manufactured off-site to Alpha Controls' specifications, including:

- Modular Construction: Individual control sections for ease of maintenance

- DOL & Inverter Starters: For fixed-speed and variable speed equipment

- Isolators & Protection: Individual circuit isolation with coordinated MCCBs

- Future Expansion: Spare capacity for additional circuits

Boiler & Heating System Integration

The Hamworthy FLEET F150 boilers were fully integrated into the new MCC panel with coordinated control and safety interlocks:

- Boiler Sequence Controller: Merley controller provides automatic lead/lag selection

- Safety Interlocks: High-limit thermostats and flame failure detection

- Pump Interlocks: Prevents dry-firing by coordinating with circulation pumps

- BMS Interface: Enable/disable signals and status feedback

Pump Control & Pressurisation Systems

Grundfos variable speed pumps were wired into dedicated control circuits with:

- Variable Speed Control: Modulating control signals from BMS

- Duty/Standby Configuration: Automatic changeover on failure

- Run Status Monitoring: Current sensing and flow switch confirmation

- Fault Indication: Overload trips and inverter faults generate alarms

Wiring & Cable Management

All new wiring was installed to BS 7671 18th Edition standards:

- Power Cables: SWA cable with appropriate gland termination

- Control Cables: Tri-rated and SY screened cable for all control wiring

- BMS Integration: Shielded twisted-pair cabling for analog signals

- Mechanical Protection: All cables routed in galvanised steel trunking

Project Benefits & Outcomes

The Watchmaker Court MCC panel upgrade delivers:

- Improved Reliability: Modern control components reduce fault frequency

- Enhanced Safety: Individual circuit isolation and comprehensive labeling

- Expansion Capacity: Spare ways accommodate future plant additions

- Energy Efficiency: Variable speed pump control and optimized boiler sequencing

Technical Specifications

Mechanical Plant

- Hamworthy FLEET F150 Boilers

- Grundfos Variable Speed Pumps

- Aquamaster Pressurisation Unit

- Inline Ventilation Fans

Control Systems

- Modular MCC Panel

- Merley Boiler Sequence Controller

- Siemens RVD110 BMS Controller

- DOL & Inverter Starters

Electrical Works

- SWA Power Cabling

- SY Screened Control Cable

- Galvanised Containment System

- BS 7671 18th Edition Compliance

Integration

- Full BMS Integration

- Safety Interlocks

- Remote Monitoring

- Energy Optimization

Need an MCC Panel Upgrade or Plant Room Retrofit?

Alpha Controls specialises in MCC panel design, manufacturing, and installation for commercial and industrial applications across London and the South East.